PREDICTIVE MAINTENANCE

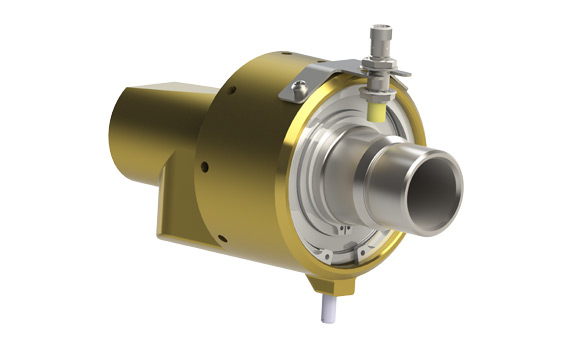

PREDICTIVE MAINTENANCE OF YOUR ROTARY JOINTS

Spontaneous defects often lead to annoying downtimes. However, planned maintenance also puts a machine temporarily out of action time and again. The way out of this dilemma is called predictive maintenance: By means of sensors, you keep monitoring the condition of your components. Wear and critical operating conditions are detected at early stages and can be remedied in a targeted manner. This means that you only carry out maintenance when it is really necessary. This reduces downtime to a minimum – and avoids unnecessary use of technicians and spare parts.The maierGROUP is the technology leader in predictive maintenance and is continuously expanding this lead. We develop sensors and communication technology specifically designed for monitoring rotary joints. Whether leakage, wear, pressure, temperature or speed: You are informed about the condition of your machine at all times and can intervene if necessary.

IDEAL FOR:

- Paper industry

- Plastics manufacturing

- Nonwoven

- 24/7 continuous operation

- Machine retrofit for Industry 4.0

RELIABLE SENSOR TECHNOLOGY

AGAINST UNEXPECTED STANDSTILLS

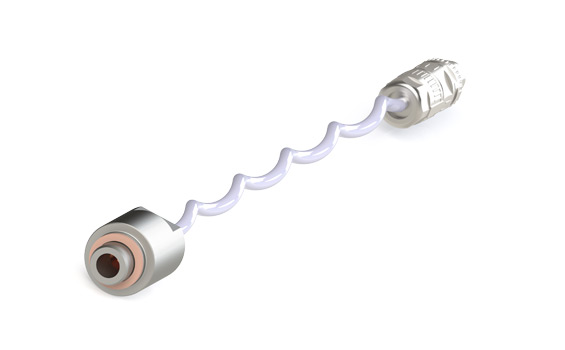

IO-Link / Link C

The communication system for your rotary joints incl. a patented interface for predictive maintenance. Awarded the Innovation Prize Ostwürttemberg 2020.

WE WILL BE HAPPY TO ADVISE YOU.

Please feel free to contact us!

Our team is looking forward to your inquiry.

Our team is looking forward to your inquiry.