ROTARY JOINTS

FOR THE PLASTICS INDUSTRY

Precise temperature control is essential in the production and finishing of plastics. Whatever technologies and processes you choose: Your rotary joints must meet all requirements one hundred percent. The maierGROUP has been supporting leading companies in the plastics industry for many years.

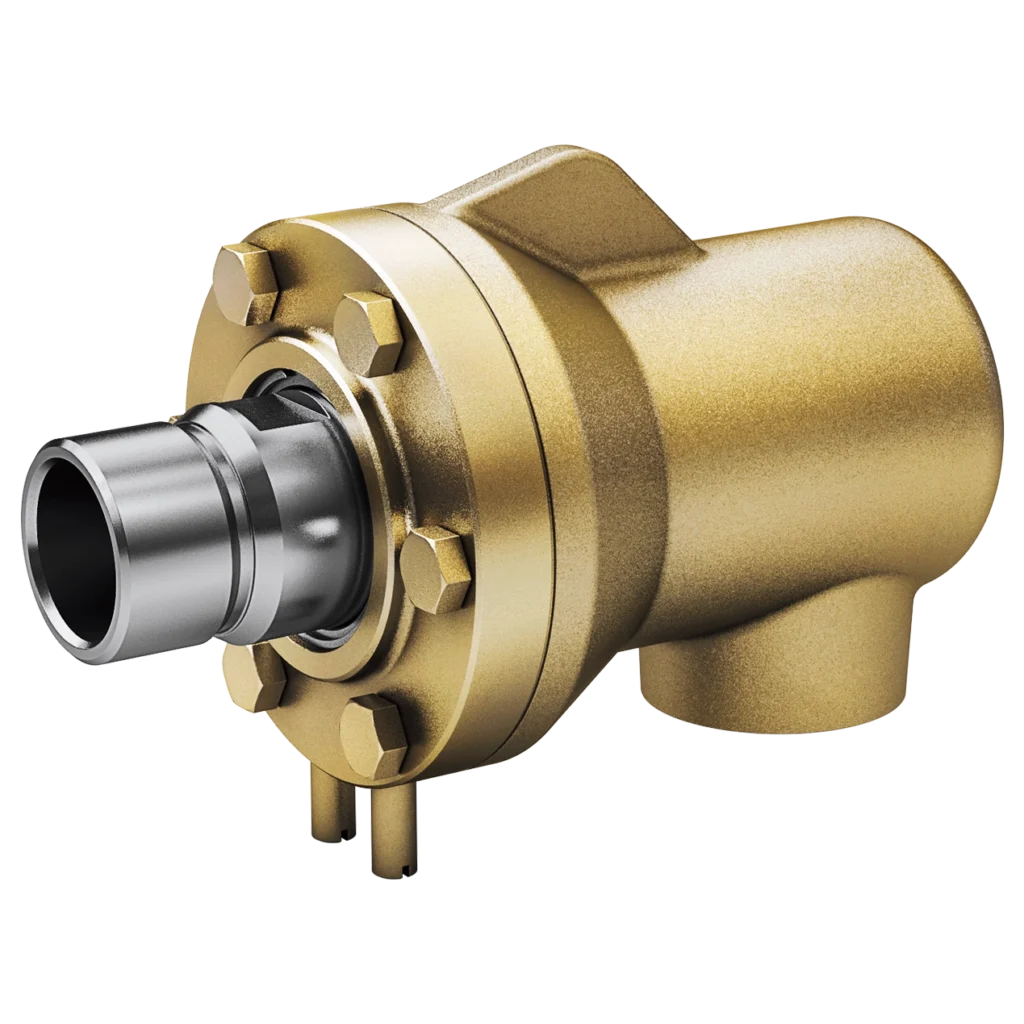

ROTARY JOINTS

FOR INJECTION MOLDING

Your application

- Production of workpieces from several combined plastics (e.g. car tail light). The injection mold must be able to rotate and swivel to different injectors.

Your advantages

- The tool can be supplied with several media simultaneously (e.g. hot water, cooling water, compressed air, and/or hydraulic oil)

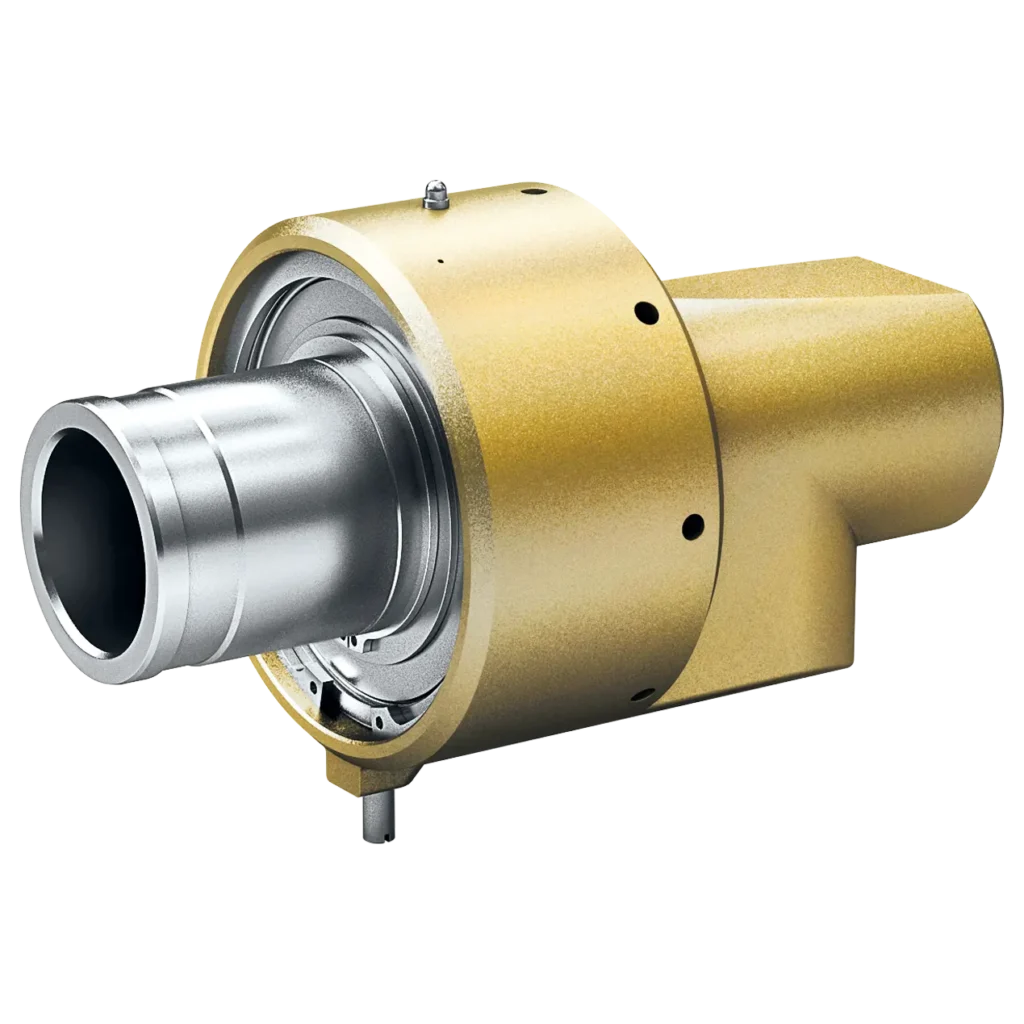

ROTARY JOINTS

FOR FILM PRODUCTION

Your application

- Cooling rolls of blown film machines, stretching rolls of MDO lines, both heating and cooling

Your advantages

- Low frictional torque, especially for non-driven rolls

Your application

- Use on cooling rollers

Your advantages

- Extremely reliable

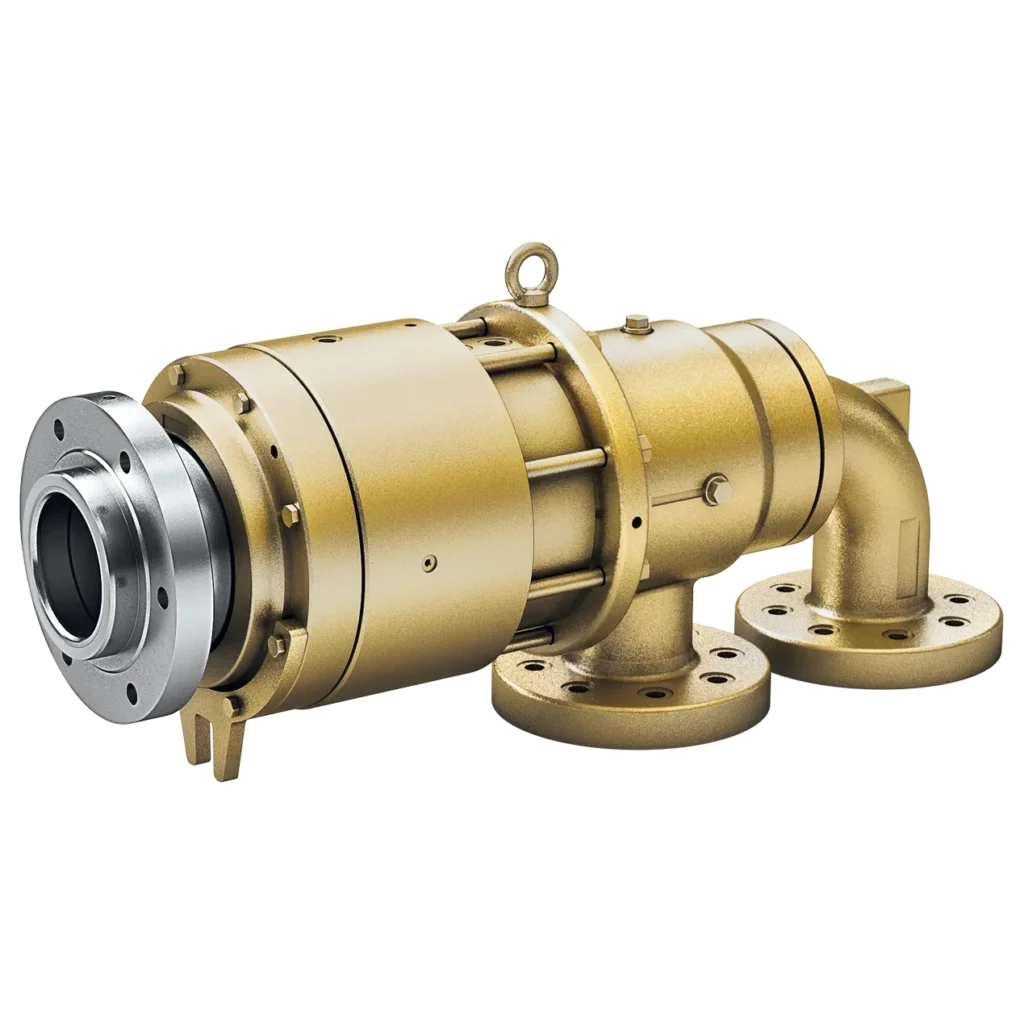

ROTARY JOINTS

FOR RIBBON SYSTEMS

Your application

- Stretching of plastic tapes on heated rollers (e.g. for woven bags or artificial turf)

Your advantages

- Compact

- Reliable

- Universal

ROTARY JOINTS

FOR REFINEMENT

ROTARY JOINTS

FOR RUBBER

YOU STILL HAVE QUESTIONS?

Get in touch with us!

Our team is looking forward to your inquiry.

Our team is looking forward to your inquiry.