REPAIR COATING

LONGER SERVICE LIFE DUE TO REPAIR COATING

Damaged machine components no longer have to be completely replaced, defective products no longer automatically end up in the scrap bin: With laser repair coating, the maierGROUP offers you an innovative process to cost-effectively repair defects on critical joining or sealing surfaces – and to significantly extend the service life of components in need of repair. A precisely applied repair layer fully restores the function of the component. You save on expensive new purchases, reduce the lead times for new production and conserve your resources. Last but not least, this benefits your company’s sustainability balance.

REFERENCE PROJECTS

IN THE REPAIR COATING

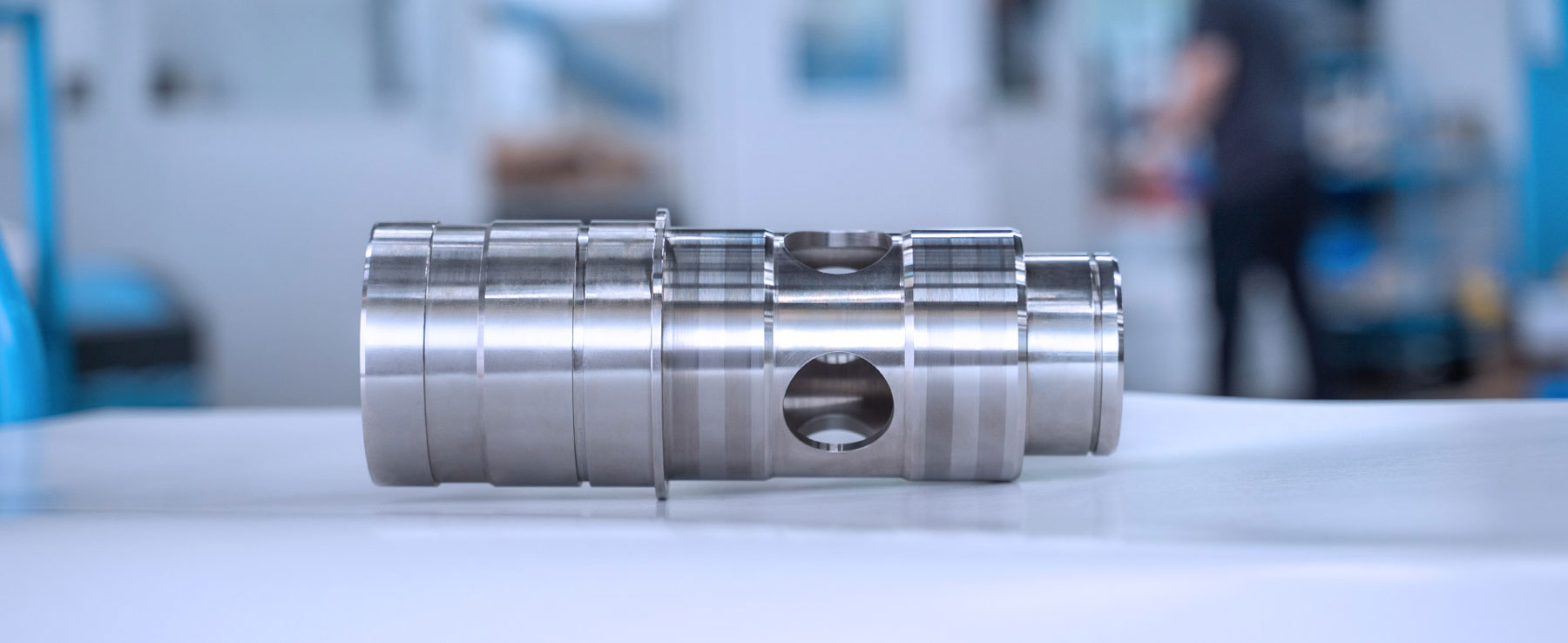

Example 1: Repair of a knocked out groove

The task:

Production errors occurred during the processing of rotors. The customer asked for a solution to repair the damaged areas and save the costly produced components.

Production errors occurred during the processing of rotors. The customer asked for a solution to repair the damaged areas and save the costly produced components.

Solution:

By building up layers, the maierGROUP was able to recondition the damaged zones cost-efficiently. A lengthy remanufacturing of the component was no longer necessary.

By building up layers, the maierGROUP was able to recondition the damaged zones cost-efficiently. A lengthy remanufacturing of the component was no longer necessary.

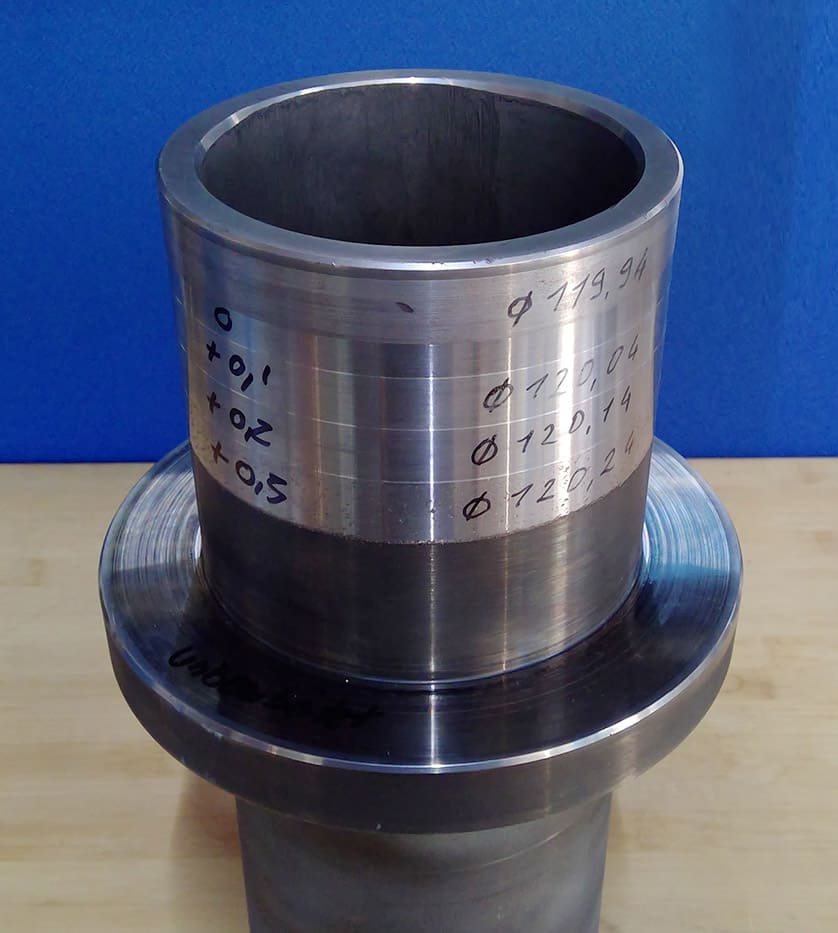

Example 2: Parts machined to the wrong dimension

The task:

During the machine finishing of a component, the dimensional tolerance was not observed.

During the machine finishing of a component, the dimensional tolerance was not observed.

Solution:

By applying a laser coating, the component could be machined again.

By applying a laser coating, the component could be machined again.

YOU STILL HAVE QUESTIONS?

Get in touch with us!

Our team is looking forward to your inquiry.

Our team is looking forward to your inquiry.