WEAR PROTECTION

LONGER SERVICE LIFE DUE TO WEAR PROTECTION COATING

Protect your components sustainably against adhesion, abrasion, surface disruption, and tribo-oxidation: The innovative laser coating from the maierGROUP gives your components resistance to wear and is an excellent alternative to hard chrome. We are experts in rotary joints. Our wear protection coating process is therefore especially optimized for sealing surfaces. And it is constantly being developed further.

We work with hard alloys, metal matrix composites, and patented oxide ceramics. Manufacturers from the mechanical engineering sector are already successfully using the wear protection coating of the maierGROUP. Our customers come from industries such as food, pharmaceuticals and cosmetics, process engineering, hydropower, mining, offshore, and automotive.

APPLICATION EXAMPLE

IN THE WEAR PROTECTION COATING

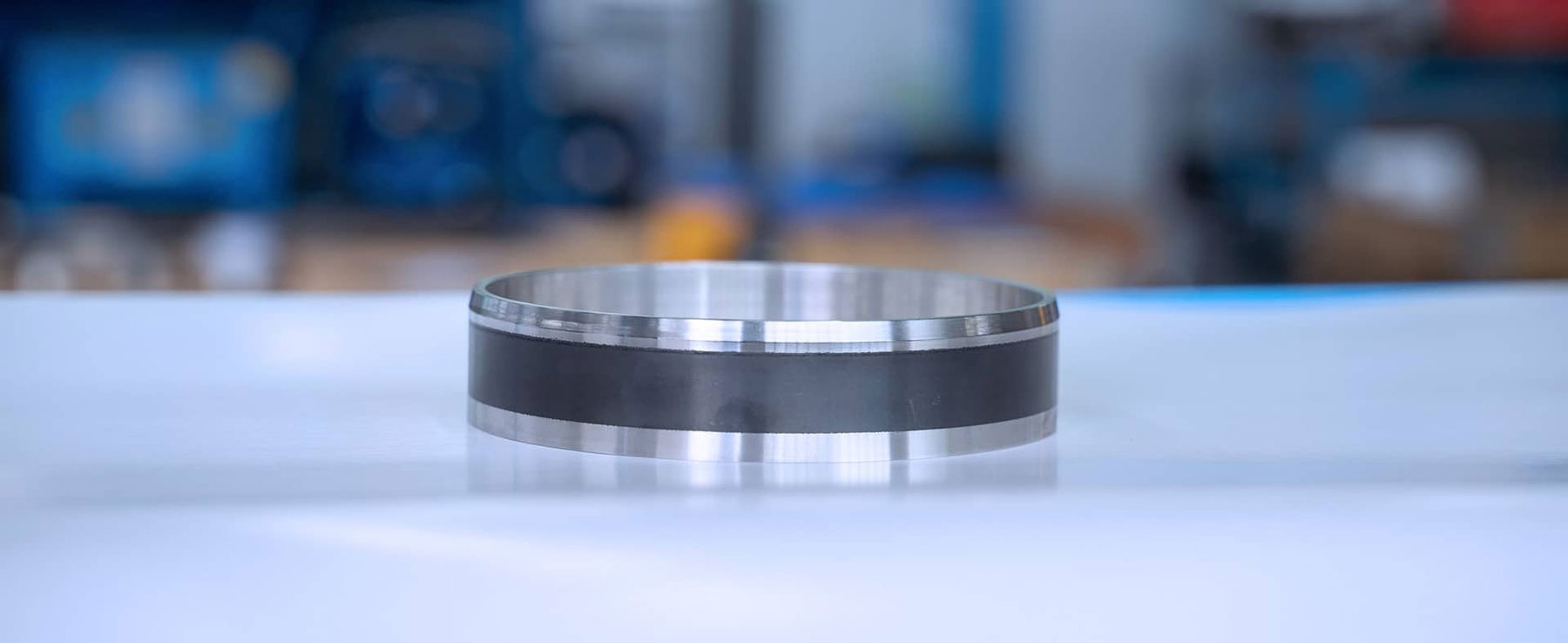

M ROTORS, DZ-ROTORS, SHAFT SLEEVE

The task:

In order to extend the service life, the service life of sealing materials is to be increased.

In order to extend the service life, the service life of sealing materials is to be increased.

Solution:

We replace thermally sprayed coatings with tribologically optimized laser clad coatings. These are much more robust against corrosion.

We replace thermally sprayed coatings with tribologically optimized laser clad coatings. These are much more robust against corrosion.

YOU STILL HAVE QUESTIONS?

Get in touch with us!

Our team is looking forward to your inquiry.

Our team is looking forward to your inquiry.