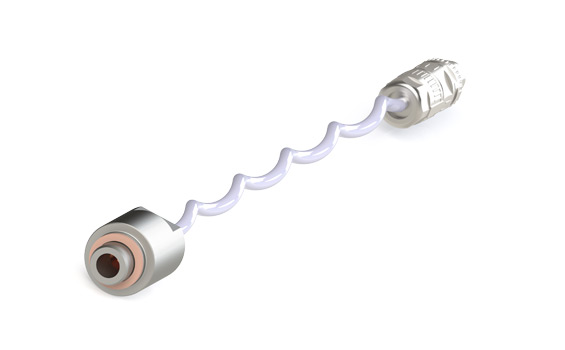

SENSE W - WEAR SENSOR

HIGHER MACHINE AVAILABILITY DUE TO PLANNABLE MAINTENANCE

You can finally put an end to uncertainty about the condition of your rotary joints: With the Sense W wear sensor, you are able to precisely plan maintenance requirements and prevent spontaneous failures. By continuously monitoring the remaining base height, you can calculate the remaining runtime and perform targeted maintenance at the right time.

IDEAL FOR:

- Paper industry

- Plastics manufacturing

- Nonwoven

- 24/7 continuous operation

- Machine retrofit for Industry 4.0

YOUR ADVANTAGES FOR THE HIGHEST RELIABILITY

Continuous

wear monitoring

Continuous monitoring of the mechanical seal makes maintenance easier to plan. In this way, you increase the efficiency of your maintenance personnel, increase machine availability, and also optimize your inventory management.

Simple

integration

The sensor technology for your rotary joints can be easily integrated into the control system using the IO-Link standard. The system is compatible regardless of the manufacturer.

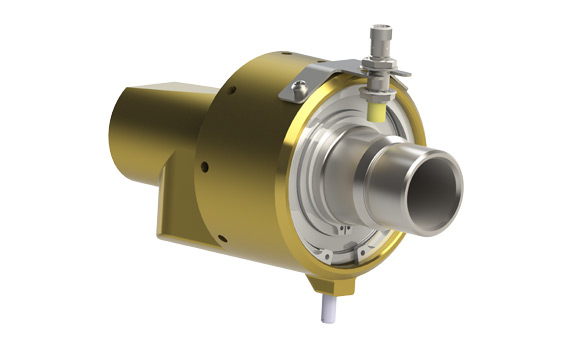

RELIABLE SENSOR TECHNOLOGY

AGAINST UNEXPECTED STANDSTILLS

IO-Link / Link C

The communication system for your rotary joints incl. a patented interface for predictive maintenance. Awarded the Innovation Prize Ostwürttemberg 2020.

WE WILL BE HAPPY TO ADVISE YOU.

Please feel free to contact us!

Our team is looking forward to your inquiry.

Our team is looking forward to your inquiry.

PREMIUM SUPPORT FROM THE EXPERT

Decades of experience of the maierGROUP have been incorporated into the development and production of your rotary joints. We see it as our responsibility to ensure that these important components of your machine or installation perform their tasks reliably. What challenge may we tackle for you?

- Everything from a single source

- Installation and installation advice

- Tailored maintenance contracts

- Personal telephone hotline

- Spare parts in stock

- Service on site

- Service support through digital signals

- Repair by the manufacturer

- Troubleshooting

- Firefighting operations on site