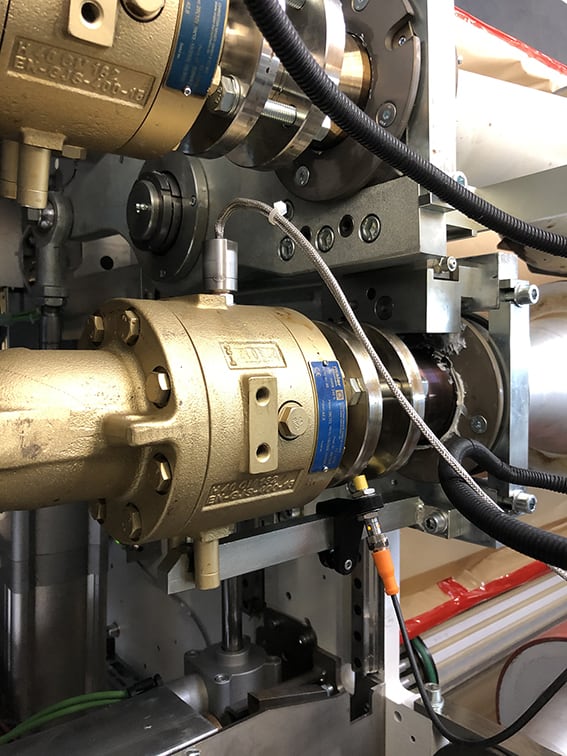

The “Link C” is an electronic interface module which is used to transfer data from various sensors connected to our rotary joints directly to the machine control or to a cloud.

The invention by Guenther Schwenk, Lukas Hoerger and Florian Maier is the central component of our Maier Connect concept. Using artificial intelligence, data relevant to maintenance, such as speed, pressure, temperature, wear, leakage and torque are evaluated in real time in order to carry out precise predictive maintenance of the rotary union. This provides both our customers and us with significant added value, as unforeseen maintenance operations or downtimes can be prevented.

What is that certain something?

The interface module enables the connection of several sensors, with the special feature of being able to convert different input signals into an IO-Link signal. This is currently unique in the industry. The IO-Link technology is an evolutionary further development of connection technologies for sensors and actuators.

With Maier “Link C” we are able to offer customers from other industries the possibility to convert analogue signals into digital signals.

In our eyes a good answer to the challenge of Industry 4.0.

We are very happy about this award, because it also shows that we are on the right way to lead our products into a new generation and thus to be able to lead the market sustainably in the future. It gives us the opportunity to offer our customers new service concepts and product lines. We are currently working on making the product ready for the market.

Interest awakened:

Mr. Manuel Schoeferle (Manuel.Schoeferle@maier-heidenheim.de) and Mr. Markus Scharting (Markus.Scharting@maier-heidenheim.de) will be happy to be there for you.